Resource consequences

Rresource-related consequences for fields without power from shore

For a number of fields, power from shore will most likely not be profitable. These fields have few opportunities to achieve major emission reductions. High CO2 costs could thus lead to negative consequences as regards resources.

For a number of fields, power from shore will most likely not be profitable. These fields have few opportunities to achieve major emission reductions. High CO2 costs could thus lead to negative consequences as regards resources.

In this chapter:

- Energy consumption on the facilities

- Consequences for improved recovery

- Phasing in third-party fields

- Fields may have shorter lifetimes

- Consequences for exploration activity

The expectation is that a number of fields will continue to operate using gas turbines; see Table 5. As shown in Figure 3, these fields will be subject to significant CO2 costs.

High costs provide an incentive to reduce greenhouse gas emissions. At the same time, the options for implementing substantial emission-reduction measures on these fields may be limited. Factors such as a short remaining lifetime, long distance to shore, and/or significant refitting needs will mean that power from shore is not profitable. For this reason, several projects to transition to power from shore have been scaled back or stopped; see Chapter 5 .

Even if transitions to power from shore are not implemented, high CO2 costs will provide an incentive for licensees to carry out operational adjustments. This could include anything from minor energy efficiency measures to earlier shutdown and/or consolidation of infrastructure. This chapter deals with potential resource-related consequences of high CO2 costs and emission reduction measures.

Table 5 (below): Fields without plans to transition to operation with power from shore. Several of these are host fields that process oil and gas, and they deliver electricity to connected fields (righthand column). *Gullfaks and Snorre receive partial electricity supplies from the Hywind Tampen wind farm.

|

Field |

Connected fields in operation and under development |

|

Alvheim |

Vilje, Volund, Bøyla, Skogul og Tyrving |

|

Brage |

Bestla |

|

Ekofisk |

Tommeliten A, Tor |

|

Eldfisk |

Embla |

|

Gullfaks* |

Gimle, Sindre, Gullfaks Sør, Tordis, Visund Sør |

|

Heidrun |

|

|

Johan Castberg |

|

|

Kristin |

Tyrihans, Maria |

|

Kvitebjørn |

Valemon |

|

Norne |

Urd, Skuld, Alve, Marulk, Verdande |

|

Skarv |

Ærfugl Nord, Alve Nord, Idun Nord, Ørn |

|

Snorre* |

Vigdis |

|

Statfjord |

Statfjord Nord, Statfjord Øst, Sygna |

|

Ula |

Oda, Tambar, Tambar Øst, Blane |

|

Visund |

|

|

Yme |

|

|

Aasta Hansteen |

Irpa |

|

Åsgard |

Mikkel, Morvin, Trestakk, Berling, Halten Øst |

Energy consumption on the facilities

Petroleum facilities need energy for several purposes including operation of the process plant, exporting oil and gas, drilling wells, heating and lighting.

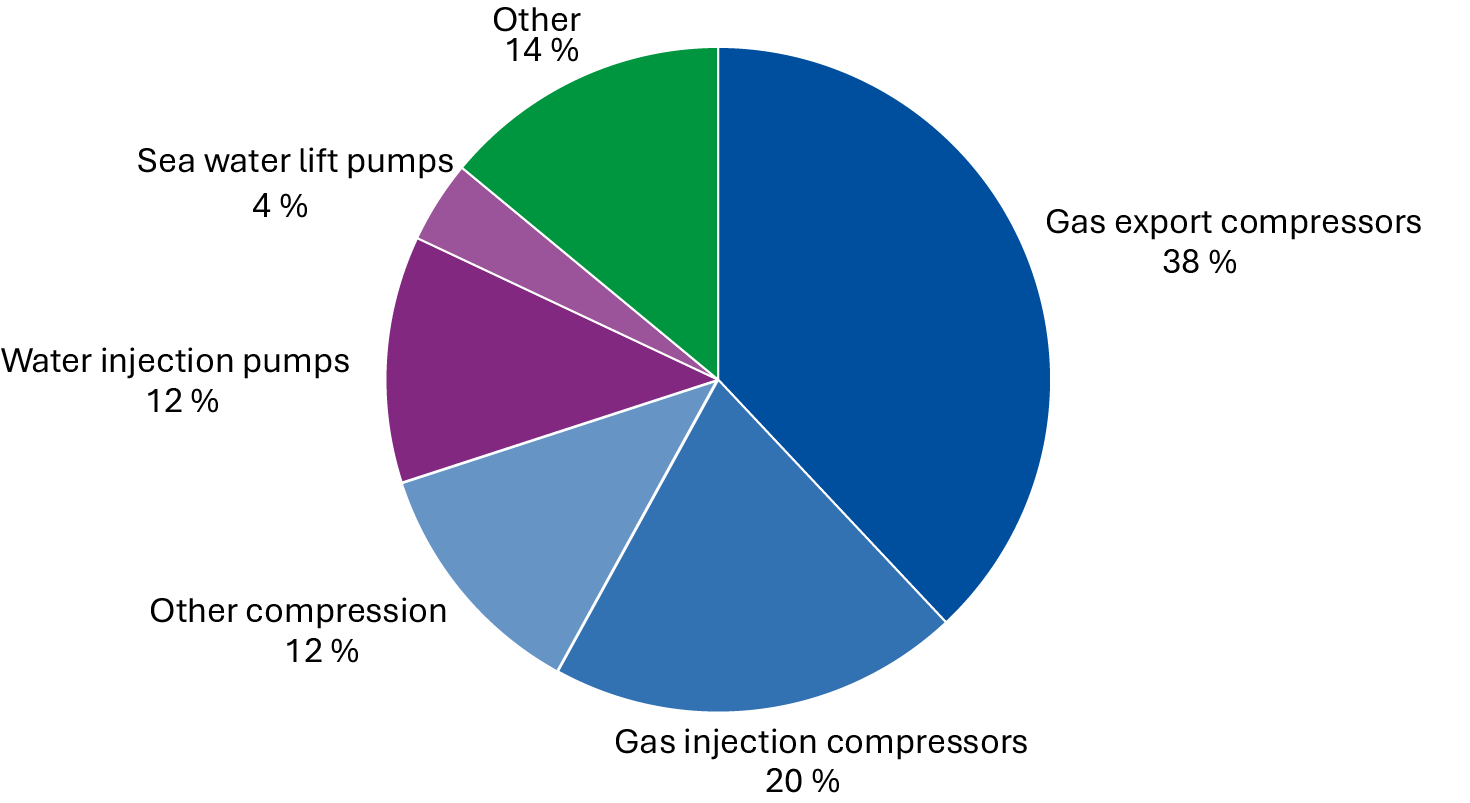

Much of this energy goes to the operation of large compressors and pumps. Gas compression is used to increase the pressure of gas for export, increased production of oil through reinjection in the reservoir or for gas lift. Pumps are also used for oil export and for water injection for improved oil recovery. Figure 5 illustrates the distribution of energy to various purposes.

High emission costs tend to promote lower energy consumption. This could result in resource consequences if energy-intensive measures are not approved.

Figure 5: Energy consumption distributed by activities (Source: Equinor,18 facilities on the NCS, 2022).

Consequences for improved recovery

For a field with energy generation based on gas turbines, environmental costs could impact the selection of recovery strategy, both for producing fields and in future projects. This is because a number of the measures that helps maintain production on the fields require energy. High CO2 costs thus contribute to reduce the profitability associated with such production measures.

One example of this is pressure support. Injection of gas or water is used in most oil reservoirs to improve recovery. A new project can require substantial investments, such as for drilling wells for this purpose. Costs in the operations phase are largely linked to energy consumption. Reduced injection of water in the reservoir on a field will reduce energy consumption, but it can also entail reduced production over the short or longer term.

Low-pressure production is another example. Declining reservoir pressure reduces the production of oil and gas over time. Production can be maintained and a higher recovery rate secured by lowering wellhead pressure or separator pressure on the facility. This is becoming increasing relevant as the fields on the Norwegian shelf grow older. Low-pressure production requires more energy because the gas that goes to injection or export must be compressed from a lower pressure.

It is difficult to estimate just how much higher CO2 costs will reduce recovery measures. Investment costs and the volume of recoverable resources will normally have greater significance for profitability as compared with costs associated with operation.

Phasing in third-party fields

Many fields on the Norwegian shelf function as hosts for third-party fields. This means that smaller discoveries in nearby areas can be connected to existing infrastructure on the host field. This contributes to extended production and lifetime for the host field. This is important in order to maximise resource utilisation and value creation, both in the area and on the NCS as a whole. The existing discovery portfolio largely consists of discoveries with expected development using subsea solutions.

The phase-in of third-party volumes can lead to an increase in overall energy consumption on the host field, either as a consequence of increased power consumption for production of oil and gas from third-party fields, or that the production is extended over time. High CO2 costs help make fields without power from shore less attractive host fields.

Conversely, fields with power from shore projects undergoing planning or development can entail higher costs for licensees that consider tying in discoveries, if they have to help cover the costs. Tying in discoveries could also be deferred because of insufficient capacity to carry out modification work offshore alongside the conversion to power from shore.

The most important factor for phasing in third-party fields appears to be that the companies are also considering the possibility that low emissions on the field/facilities may be a precondition for continued operation over time. Fields that do not have low emissions could thus become less relevant as host facilities for new subsea fields.

One consequence of this could be the selection of more expensive electrified tie-in alternatives. This could also lead to a backlog of projects to the same host facility, such that fields are commissioned later, fields without power from shore are shut down earlier and/or exploration in the nearby area declines.

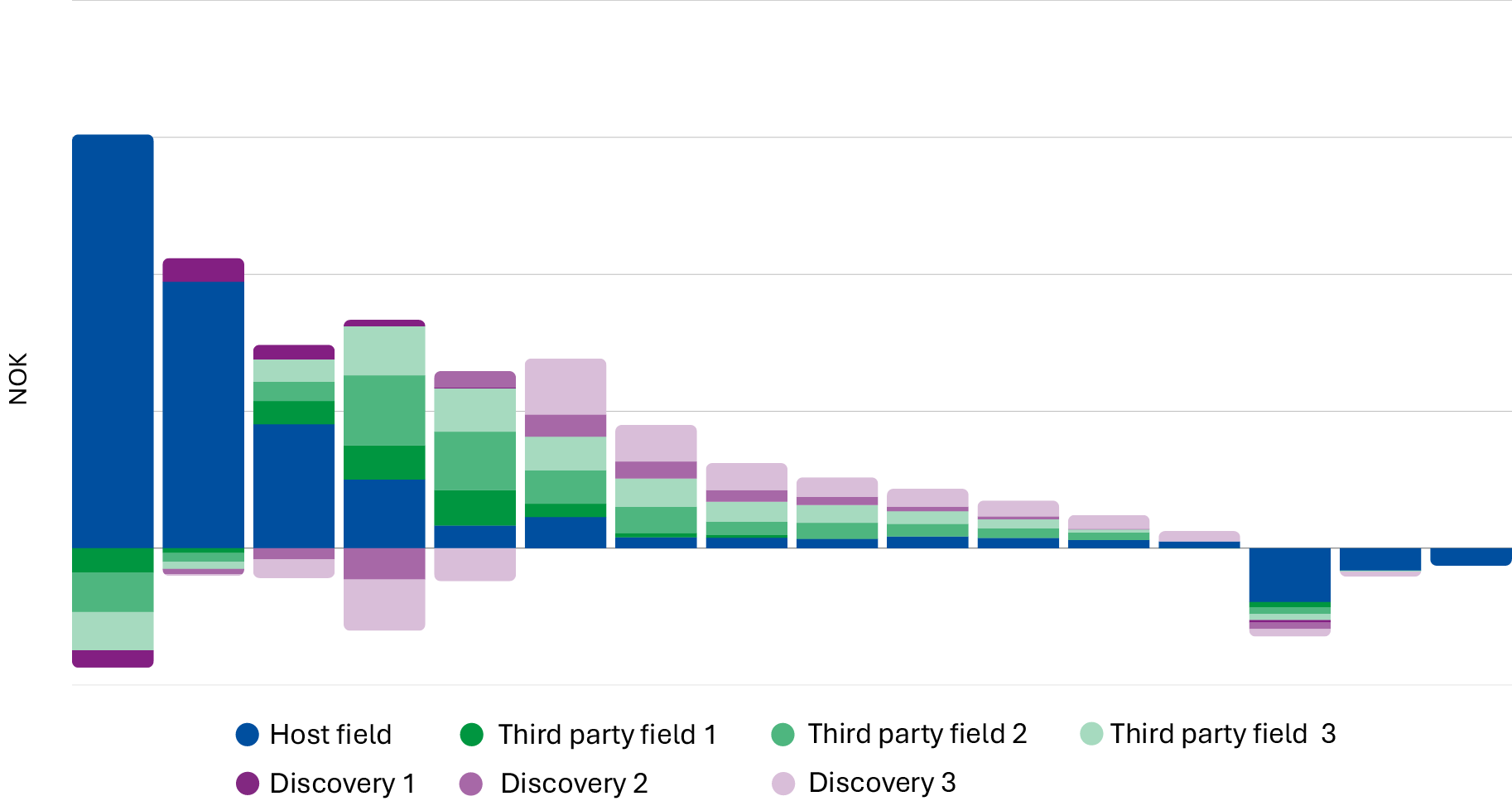

Figure 6 below illustrates cash flow for all resources linked to a host facility. The overall value grows when multiple fields share the cost of using existing host facilities.

Figure 6: Estimated future cash flow for host fields and third-party fields (sample fields). With third-party fields and discoveries tied into host fields, the shutdown date in this example is 2037. When multiple fields share the cost of using existing host facilities, this increases overall value and contributes to extending lifetimes.

Fields may have shorter lifetimes

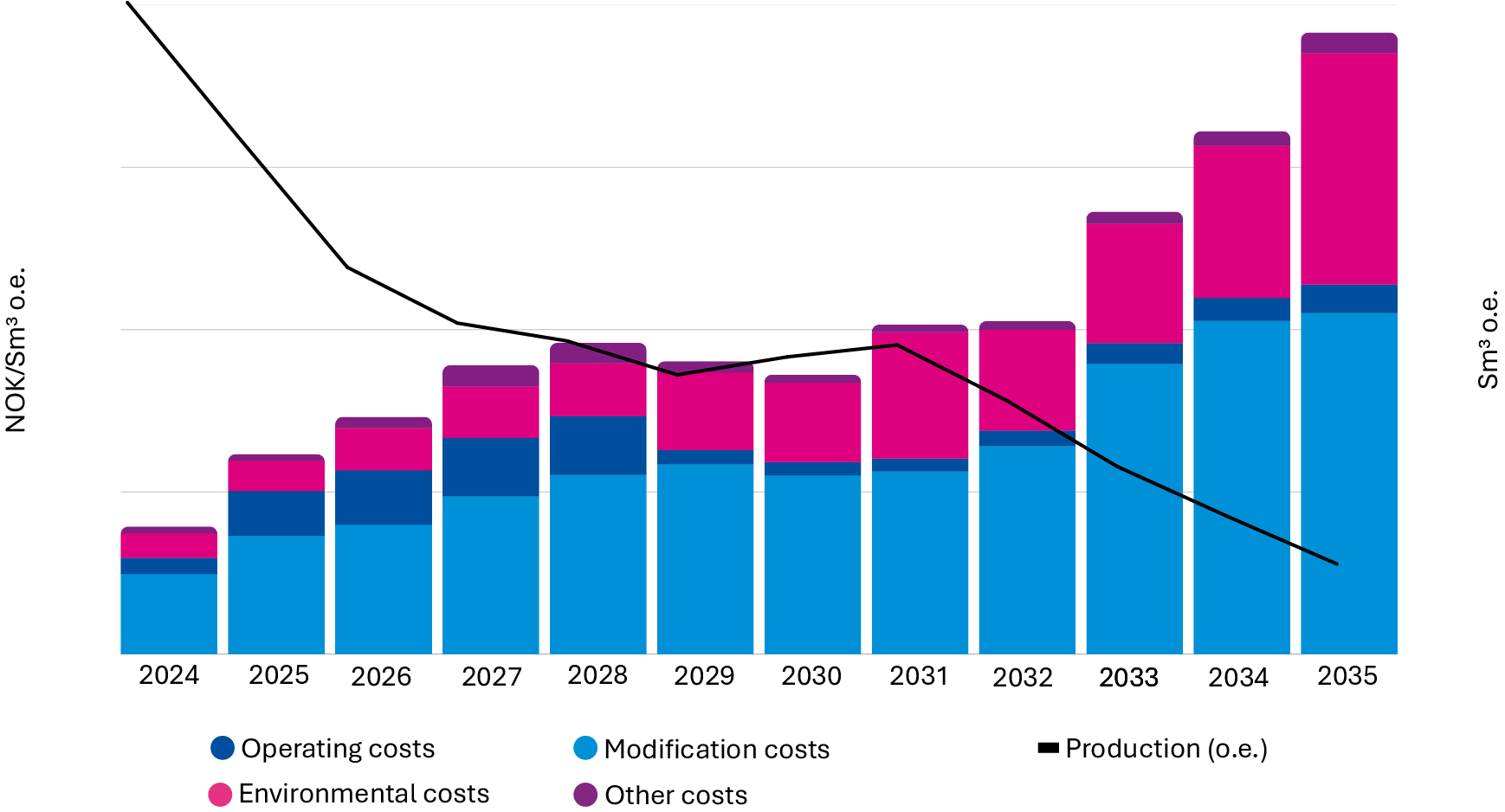

Under normal circumstances, a field has just a few years at plateau production, followed by a relatively long period of tail production . Operating costs can be relatively stable. This results in gradually increasing costs per produced unit, and a decline in cash flow; see Figure 7. Increasing environmental costs lead to a further reduction in positive cash flow, and can contribute to accelerating shutdown.

To offset this effect, licensees will consider reducing energy consumption and the number of turbines in normal operation. The extent to which energy consumption can be reduced, and how this might potentially affect recovery over the shorter and longer terms, will vary. Projections indicate that a relatively large increase in CO2 cost would have to occur in order to entail any substantial curtailment of the production period.

One alternative to a complete shutdown of the activity on a field may be consolidation, in the form of shutting down parts of the infrastructure on the field.

Figure 7: Development in cost per produced unit (sample field).

Consequences for exploration activity

The vast majority of future developments of new discoveries are expected to consist of subsea solutions tied into nearby infrastructure.

If existing fields and infrastructure are shut down, or if capacity is reduced due to consolidation, the development of these discoveries will become more expensive and more complex. This will particularly be the case where there is no alternative infrastructure nearby. This could lead to lower exploration activity because it undermines profitability.

Updated: 10/29/2025